5 Issues Created by Inexpensive Steel Buckles and How to Avoid Them

2025-10-30Steel buckles may look small, but they play a big role in securing goods during packaging and transport. Many businesses opt for inexpensive buckles to save on costs, but this decision often leads to major problems—broken straps, rust, and even product damage.

In this article, we’ll explore five common issues caused by low-quality steel buckles and explain how to avoid them by choosing durable, high-performance options from Weide Chuangyi Packaging.

Issues 1:Strap Breakup During Use

Why Cheap Buckles Fail So Easily

Inexpensive steel buckles are frequently produced with substandard steel that doesn’t provide the tensile power needed to bear down on high forces used during strapping. Such buckles are weak points that can easily crack, bend, or snap when put through dynamic loads or long-distance hauls. Inconsistent thickness, combined with poor-quality galvanizing, also weakens the structural integrity. Used with PET or PP strapping for heavy-duty operations such as logistics, cartridge or machinery shipping, these points of weakness are key points for failure. Going for low-priced resources will sometimes sacrifice quality, so care must be exercised during procurement. This directly applies to steel buckles, too—if the steel is thin or not nicely treated, it doesn’t hold up.

How Quality Materials Prevent Breakdowns

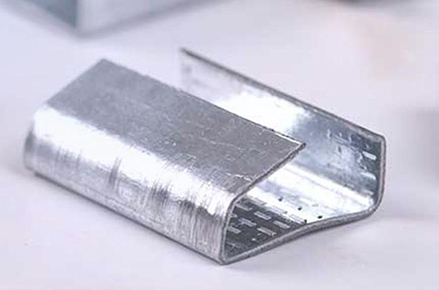

Quality buckles are produced using galvanized steel with uniform thickness and an accurate dimension. Not only will the buckle gain in toughness when using galvanized steel, but resistance to environmental stress conditions is also improved. With the use of strong materials, the buckle is assured of many repeated stress occurrences without deformation or breaking. With the ability to seal polypropylene, polyester, or steel straps, the PET strap steel buckle by Weide Chuangyi Packaging is specifically designed for durability, making it suitable for heavy-duty operation, providing a sound solution for banding goods during shipping.

Reliable Performance with Weide Chuangyi Packaging

Weide Chuangyi Packaging manufactures steel buckles, including the likes of 16mm*0.5mm, 19mm*0.5mm, and 19mm*0.8mm, all constructed using high-grade, strong, and quality galvanized steel. Simply place the split clamp on the strap ends with overlap before or after tightening before crunching with the use of the hand tool—the usability combined with high-grade quality ensures the best performance for the long term. All the products undergo stringent production controls with quality and are also put through severe testing to ensure that the buckles pass the standards required in the industry, even where high-force conditions, such as palletizing in the ceramic business or machinery shipping, are involved.

Issues 2: Slipping Off or Loosening When Tensioned

Why Low-Quality Buckles Lose Grip

Cheap buckles often have irregular surfaces, improper tooth alignment, or insufficient clamping force—yet all these are sources for slippage when subjected to force. Consequently, packages loosen with time, with the risk of damaging or collapsing when shipping. If the upper and lower bands are not fully aligned, adjust using the buckle. This highlights how critical proper buckle alignment is for secure strapping.

The Power of Precision Engineering

Precision-engineered buckles offer consistent grip by maintaining tight tolerances in manufacturing. Accurate teeth profiles ensure that once crimped, the strap remains locked without slippage—even under fluctuating loads or vibrations during transport. Weide Chuangyi Packaging’s manual strapping tools, like our Poly Strapping Sealer, ensure a firm lock when used with our steel buckles, thanks to their compatibility with 12–19 mm wide straps and ergonomic design for maximum pressure application.

How Weide Chuangyi Packaging Ensures Firm Locking

Facilitates fast and efficient strapping of large batch jobs, our buckles are engineered for compatibility with PET and PP straps to deliver strong locking performance. Combined with our manual tools, such as the Strap tensioner for wide strapping bands 12 to 19 mm, users experience minimal risk of loosening even under extreme conditions.

Issues 3: Rust and Corrosion Over Time

Why Inferior Coatings Lead to Rust

Buckles lacking proper anti-corrosion treatment quickly degrade when exposed to moisture or harsh environments. Rust compromises both appearance and mechanical strength, making them unreliable over time—especially in humid warehouses or outdoor storage. The goods can be directly packed with PET strapping tape without damage or corrosion. However, if paired with rust-prone buckles, this advantage is lost.

Importance of Galvanization

Galvanization is essential for preventing corrosion. A quality galvanized coating forms a protective barrier against oxidation while maintaining structural integrity across seasons and weather conditions. Weide Chuangyi Packaging uses galvanized steel exclusively for its steel buckle line, ensuring resistance against rust even in coastal climates or long-term storage scenarios.

Long-Lasting, Rust-Free Performance

Our galvanized PET strap steel buckle models are designed specifically for rust-free performance. Products include Strap Series, Winding Film Series, Baler Machines, Accessory Products—our accessory line includes only components that meet our stringent quality requirements, including anti-corrosion properties suitable for industrial use across sectors like ceramics, electronics, hardware, and logistics.

Issues 4: Damage to PET Strapping

The Problem with Rough Finishing

Low-grade buckles often have burrs or sharp edges due to poor cutting techniques or a lack of finishing processes. These imperfections can easily cut into PET straps during tensioning or transport vibration—leading to premature failure of the strapping system. The edges are smooth and will not hurt your hands or damage the packaged objects. This describes exactly what high-quality packaging components should offer—not just safety but also strap protection.

Smooth Design for Strap Protection

A well-designed buckle features smooth curves and rounded edges that protect the integrity of PET strapping while maintaining grip strength. This ensures longevity of both strap and seal without compromising safety. Our PET strapping belt/Heavy Duty Packing Belt works seamlessly with Weide Chuangyi Packaging’s precision-finished buckles—ensuring no fraying or tearing occurs at contact points during application or handling.

Safe and Reliable for Every Application

All our steel buckle models undergo CNC machining followed by deburring processes that eliminate sharpness while preserving functionality. Weide Chuangyi Packaging—We take pride in delivering packaging solutions that prioritize both performance and product protection across all industries we serve, including home appliances and mechanical parts sectors.

Issues 5: Improper Sealing or Locking

Why Cheap Buckles Misalign

Poorly manufactured buckles often suffer from dimensional inconsistencies, causing misalignment when applied using manual tools. Deformed shapes lead to improper sealing, which weakens package security significantly—especially dangerous when transporting heavy items like iron cans or ceramics. Open the strapping plier and place it over the metal buckle, ensuring the buckle is fully engaged with the plier’s teeth. This step illustrates how crucial proper engagement is between tool and buckle—and how deformation ruins this process entirely.

Consistent Sealing with Accurate Manufacturing

Precision-manufactured buckles hold their shape under pressure due to controlled production parameters such as thickness tolerance and punch accuracy. This guarantees consistent sealing every time they’re crimped using compatible tools like our manual sealer series. We recommend pairing our manual baler tools (tensioner + sealer) with our matching-sized steel buckles (e.g., 16mm x 0.5mm) for optimal results across various packaging applications, including logistics pallets and electronics cartons.

Secure Locking with Weide Chuangyi Packaging

All Weide Chuangyi Packaging components undergo rigid inspection—even raw material purchasing to final product checking—to ensure smooth compatibility between strapping (e.g., our PET packing belt strap) and accessories (e.g., our steel buckle strap). Custom-made strapping in PP/PET. Color specification customization possibilities also exist, so customers receive exactly the results they need according to operational requirements.

Conclusion

Choosing low-cost buckles might seem economical, but in the long run, they can lead to product loss, rework, and safety concerns. Reliable packaging starts with reliable components. With Weide Chuangyi Packaging’s galvanized steel buckles, you gain superior strength, corrosion resistance, and consistent sealing performance—ensuring that every shipment arrives safe and secure.

Ready to upgrade your packaging reliability? Contact Weide Chuangyi Packaging for durable PET and PP strapping solutions that stand up to real-world challenges.

FAQ

Q: What is the material for steel buckles?

A: Steel buckles are manufactured using high-grade galvanized steel specifically for use with PET and PP straps across a range of widths, including the 16mm–19mm widths.PET strap steel buckle

Q: Are the goods compatible with manual balers?

A: Yes! Our accessories also have compatible manual tools, including the Packing pliers manual and the Strap tensioner for wide strapping bands 12 to 19 mm for easier application, even during field application.

Q: Will the goods corrode when exposed to the atmosphere?

A: No—thanks to the effect of the galvanization, which inhibits rust even during high-moisture conditions. It has an excellent balance between -50℃ and 100℃.

Q: Can the sizes be customized?

A: Yes! Customized sizes in PP/PET strapping. Color specification customization possibilities allow customers to customize according to their required needs, including adjustments in sizes for different loads.