Hand Stretch Film Misuse: 7 Costly Errors and How to Prevent Them

2025-10-16

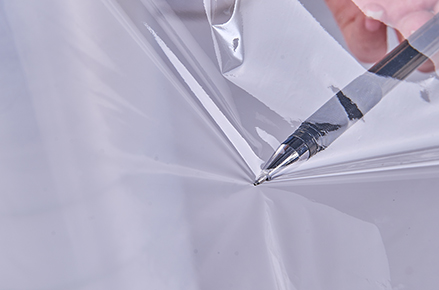

Common Misconceptions About Hand Stretch Film

Misunderstanding Film Thickness and Strength

One of the most common misunderstandings about hand stretch film is assuming that thicker film automatically means stronger protection. In reality, strength is determined not just by thickness but also by the film’s material composition and performance characteristics. For instance, PE stretch wrap is made of high-quality LLDPE as a raw material. It has the characteristics of high tensile strength, large elongation, good self-adhesion, high transparency, and excellent tear resistance. This means a thinner high-performance film can outperform a thicker low-quality one.

Assuming All Films Perform the Same

Some users believe all hand stretch films are interchangeable. However, different films are designed for different applications. At Weide Chuangyi Packaging, we offer both machine and hand-applied stretch films with varying widths (100–1400mm) and thicknesses (0.018–0.050mm) to accommodate diverse packaging needs.

Overlooking the Role of Load Type

Another misconception is ignoring how load type affects film choice and wrapping technique. Heavy or irregular loads require stronger films and more secure wrapping strategies compared to lightweight or uniform items.

7 Costly Errors in Hand Stretch Film Use

Error 1: Using Incorrect Film Thickness

Consequences of Too Thin or Too Thick Film

Using a film that’s too thin can lead to tearing during application or transit, while overly thick film increases material costs without necessarily improving load stability. Both scenarios result in inefficiency and potential product damage.

Matching Thickness to Load Requirements

It’s essential to match the film thickness to your load type. For example, our hand stretch film options on our official website come in various gauges suitable for different weight classes and shapes. Our experts can help you determine whether a 0.025mm or 0.035mm thickness is appropriate based on your specific packaging application.

Error 2: Insufficient Pre-Stretching

Why Pre-Stretching Matters

Pre-stretching enhances the film’s elasticity and holding force while reducing material usage. Without adequate pre-stretching, the wrap may not cling tightly enough to stabilize the load during transport.

Signs of Under-Stretched Film

If you notice sagging film or shifting pallets during handling, it’s likely due to an under-stretched application. Our stretch films are engineered with strong self-adhesion properties that activate when properly stretched—preventing goods from falling off.

Error 3: Wrapping with Too Few Layers

Risks of Inadequate Layering

Applying too few layers compromises containment force and increases the risk of product movement or collapse during transportation.

Recommended Layer Guidelines by Load Type

For light loads, two layers may suffice; medium loads often require three; heavy or irregular items might need four or more layers, depending on their shape and weight distribution. Our team at Weide Chuangyi Packaging can advise on optimal layering based on your use case.

|

Load Type |

Layers Recommended |

Notes |

|

Light |

2 |

Small, uniform items |

|

Medium |

3 |

Standard pallets |

|

Heavy/Irregular |

4+ |

Use corner protectors |

Error 4: Poor Wrapping Technique

Uneven Tension During Application

Inconsistent tension causes weak points in the wrap where stress concentrates—leading to tears or slippage. Hand-applied wraps should maintain steady tension throughout the process.

Improper Wrapping Angles and Overlaps

Incorrect angles or insufficient overlaps reduce structural integrity. A standard overlap rate of 30–50% between layers ensures better bonding and durability under strain.

Error 5: Ignoring Load Shape and Weight Distribution

Adapting Wrapping Technique to Irregular Loads

Irregular shapes require strategic wrapping techniques such as cross-wrapping or reinforcing corners using accessories like paper corner protectors from Weide Chuangyi Packaging. It makes the entire package stronger, reinforces the pallet, and prevents it from collapsing due to tilting.

Stabilizing Top-Heavy or Asymmetrical Pallets

Top-heavy loads benefit from extra top wraps and diagonal banding methods for added support. Our stretch films offer excellent tear resistance even when used in complex configurations.

Error 6: Using Low-Quality Stretch Film

How Inferior Film Leads to Breakage and Waste

Low-grade films often lack consistent thickness, tensile strength, or adhesion—leading to frequent breakage during use and higher consumption rates due to re-wrapping requirements.

Advantages of Weide Chuangyi Packaging’s High-Performance Films

PE stretch wrap has the characteristics of high tensile strength, large elongation, and good self-adhesion, making it ideal for secure packaging across industries like electronics, hardware, logistics, furniture, and more. Our hand stretch films are manufactured under strict quality control in our independent 10,000 square meter facility located in Foshan City.

Error 7: Failing to Train Staff Properly

Common Operator Mistakes from Lack of Training

Untrained staff may apply inconsistent tension, skip necessary overlaps, misjudge layering needs, or use unsuitable products—resulting in compromised load safety.

Building a Consistent Wrapping Process

Standardized procedures combined with hands-on training ensure consistency across shifts and locations. We recommend developing SOPs tailored to our stretch film roll products for the best results.

Best Practices for Efficient Hand Wrapping

Choosing the Right Weide Chuangyi Packaging Product

Our product range includes hand stretch film, machine stretch film, PP strapping belt, PET strapping belt, paper edge protectors, and more—all customizable by width, color, core size (76mm), etc., as listed on our official website. Customers can select specifications matching their operational needs precisely.

Implementing a Standardized Wrapping Procedure

Establish clear guidelines for pre-stretch levels (typically 150–250%), overlap percentage (30–50%), number of revolutions per layer zone (top/middle/bottom), and inspection checkpoints post-wrap.

Monitoring and Adjusting Based on Load Performance

Regular audits help identify recurring issues like shifting loads or excessive material use—enabling adjustments in technique or product choice accordingly.

FAQ

Q: What is the standard core size for Weide Chuangyi Packaging’s hand stretch films?

A: Core Size is 76mm.

Q: Can I customize the color or size?

A: Yes, we provide personalized customization, color customization, and size customization.

Q: What makes your hand-stretch film superior?

A: It has the characteristics of high tensile strength, large elongation, and excellent tear resistance.

Q: Where can I view all available products?

A: Visit for full details on our packaging solutions, including strapping belts and corner protectors.