Prevent Downtime: Choosing the Right PP Machine Strapping Tape for Your Baler

2025-11-13In modern automated packaging lines, every second of uptime counts. Whether in logistics, manufacturing, or warehousing, the efficiency of your baler depends heavily on the quality and compatibility of your PP machine strapping tape. Using the wrong tape can slow production, increase wear, and raise costs.

This guide from Weide Chuangyi Packaging explores how to choose the right PP tape to prevent downtime and ensure smooth, reliable packaging operations.

Why PP Tape Compatibility Matters

Most firms are unaware of how much a poor tape match affects productivity and maintenance. When the tape diameter, thickness, or tensile strength does not meet your baler’s specifications, it will cause improper seal, slippage, and additional in-process delays.

The hidden cost of downtime and repair

Every minute that a packaging line is down is money in terms of lost productivity, labor, and potential damage to the product. Incompatible or inferior PP strapping belts shorten the wear and tear of internal baler parts, leading to higher maintenance and even premature equipment failure. Jamming and production downtime are more than just frustrating; they are expensive in the long term.

How tape quality affects machine performance

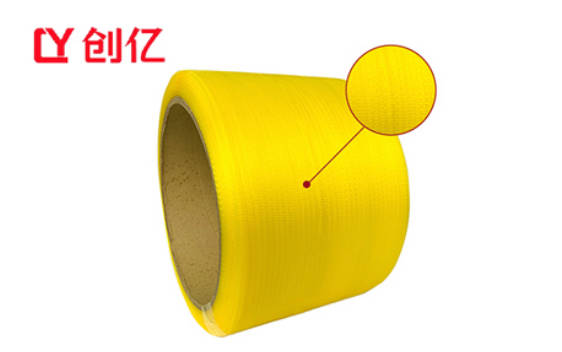

Low-quality PP strapping belts may be of uneven thickness, possess low bonding strength, or have surface irregularities. These faults increase machine friction, reduce tensioning accuracy, and lead to misalignment during high-speed operation. High-quality PP raw materials produce packing tapes of bright colors, improved, and more resistant. Poor choice of material undermines efficiency and safety.

Understanding PP Machine Strapping Tape

What is PP strapping tape made of

PP strapping belts, or polypropylene straps, are made predominantly of polypropylene resin—a lightweight plastic that is strong and capable of bending. PP bands are widely used because they are good in plasticity, have high tensile strength, resistance to bending, are lightweight, and are easy to handle.

Principal Traits Affecting Compatibility

When selecting PP tape, consider:

-

Width: 5–15mm (fully automatic machines typically apply 6–13mm).

-

Thickness: 0.6–1.2mm (automatic machines typically require 0.6–0.9mm).

-

Tensile Strength: Should be compatible with machine requirements.

-

Roll Length: Make sure it is compatible with your feeding system.

Manual vs machine-grade tape differences

Hand-grade tapes are thicker (max. 1.3mm) for hand tensioning equipment and have lower elongation tolerance. Machine-grade PP strapping belts, however, must be thinner and stronger to perform optimally in automatic balers without snapping or jamming. Highly automated machine bands are recommended with 6-13mm width and 0.6-0.9mm thickness.

Hazards of Using Incompatible or Poor Quality Tape

-

More Machine Wear: Low-grade tapes with burred edges or irregular thickness rub against tensioners and rollers, accelerating wear on vital parts like sealing heads.

-

More Frequent Jamming and Delays: Irregular bonding and uneven thickness form misfeeds, seal failures, and frequent jams, stalling workflow and requiring manual intervention.

-

Higher Maintenance Costs: All these problems add up in terms of higher maintenance costs, both in labor and replacement parts.

Expenditure on high-grade, compatible PP tape yields returns in the long run.

The System Solution to Strapping

Why the machine and tape need to be a system

A strapping system needs to be seen in the round: the tape needs to supplement the mechanical properties of the baler for maximum performance. Tension limits, sealing technique (e.g., friction welding), and feed mechanism—all have to be compatible with the spec of the PP machine strapping tape being used.

Advantages of selecting matched components

When you utilize components meant to be used in conjunction—such as our fully automatic PP strapping tape from Weide Chuangyi Packaging and our pneumatic baler PET strap pneumatic baler—you experience smoother performance, reduced breakdown, uniform tensioning, and better sealing reliability.

How Weide Chuangyi Packaging ensures compatibility

Weide Chuangyi Packaging has over 20 years of history in producing customized packaging solutions made based on unique customer specifications in industries such as logistics, electronics, ceramics, hardware, appliances, etc. We are expert manufacturers of PP strap, PET strap, and automatic PP strap. Our R&D department collaborates hand-in-hand with customers so as to ensure that machines and tapes collaborate smoothly with each other.

Choosing the Best PP Strapping Tape

Factors to Consider

-

Application type (carton vs. pallet)

-

Load weight

-

Environmental conditions (humidity, temperature)

-

Machine type (manual, semi-automatic, automatic)

-

Sealing speed and mechanism

Evaluating Tape Quality

High-quality PP tape should have:

-

Virgin polypropylene only (no recycled fillers).

-

Smooth, burr-free cross-section.

-

Uniform thickness across the roll.

-

High tensile strength (>100kg for light types).

-

Clean surface with negligible dust release.

-

Hard bonding but soft touch for sure sealing.

Advantages of Weide Chuangyi Packaging Solutions

Precision-matched machines and strapping belts

We offer accuracy-designed packages like our PET strap pneumatic baler, which is adaptable to both PP and PET straps universally, with perfect alignment of feed mechanisms to belt sizes to ensure trouble-free operation.

Consistent performance on high-speed operations

Our 5mm PP strapping tapes are used in high-speed, fully automatic machines in the logistics center or factory production line, where unscheduled downtime is costly. Low resistance to feed cycles is available on the smooth surface pattern, and the anti-slip design maintains the stability of the packages even at high speeds.

Less maintenance due to quality material

All of our products undergo rigorous quality control. Double-checking of each product has been done to meet or exceed standard quality standards. Our use of virgin polypropylene ensures longevity and lessens stress on your equipment’s internal systems—ultimately lowering repair requirements.

Best Practices for Maintenance and Operation

Regular inspection of machines and tapes

-

Check rollers for built-up residues.

-

review tension settings every week.

-

observe seals for adequate bonding.

-

test new roll before extensive use.

-

change blades worn out early.

Proper storage of PP strapping belts

-

Keep rolls standing in cool, dry places away from sunlight that deteriorate plastic polymers with the passage of time.

-

Do not pile heavy weights on rolls, which could misshape them.

-

Turn stock over regularly using the FIFO (First-in-First-out) process.

Training staff on proper usage procedures

-

Ensure operators understand how to properly load rolls into machines.

-

Train them in adjusting tension settings based on package weight.

-

Train them in manipulating techniques, especially when working with manual devices like our Poly Strapping Sealer & Poly Strapping Tensioner packages.

Conclusion

Selecting the right PP machine strapping tape is not just a small detail—it’s a key factor that determines the reliability and profitability of your packaging process. With Weide Chuangyi Packaging’s high-quality, fully compatible strapping solutions, you can minimize maintenance, boost productivity, and achieve long-term operational efficiency. Contact our experts today to find the best tape and system setup for your baler.

FAQ

Q: Should manual-grade PP straps be used on a full automatic machine?

A: No. Manual-grade straps tend to have varying thicknesses unsuitable for automated feeding systems that require precision tolerances.

Q: What is the ideal specification for fully automatic machines?

A: The ideal specification suggested for fully automatic machine bands is 6-13mm width and 0.6-0.9mm thickness.

Q: Do you offer custom colors or branding?

A: Yes! We offer customized personalization—color customization, size customization, and logo customization.