Why Fully Automatic PP Strapping Tape Is Revolutionizing the Packaging Game?

2025-11-14Good, effective, and low-cost packaging is imperative in the high-speed manufacturing and logistics industries of today. Semi-automatic or manual strapping using conventional methods will not work, leading to unbalanced tension, machine jams, and higher labor expenses. When companies expand, these antiquated methods are apt to slow down production and also damage products during transportation. Fully automatic PP strapping tape is revolutionizing the packaging sector by offering seamless compatibility with high-speed balers, consistent performance stability, and reduced downtime. Weide Chuangyi Packaging offers top-quality, fully automatic PP strapping tape to be utilized in advanced automated packaging machines.

What Is Fully Automatic PP Strapping Tape?

Key Features and Materials

Fully automatic PP strapping tape is made from high-quality polypropylene (PP) resin, a lightweight but durable plastic material. Its characteristics are:

-

High tensile strength and bending resistance

-

Excellent flexibility and durability

-

Lightweight design for easy handling

-

Long-lasting, bright color

All of these characteristics make PP strapping tape well-suited to high-speed automatic packaging machinery, offering even tension and secure bundling.

Distinctions between Manual and Semi-Automatic Tape

In contrast to manual or semi-automatic straps, completely automatic PP tape is meant to be run continuously with little human touch. Its specifications are:

-

Width: 6–13 mm

-

Thickness: 0.6–0.9 mm

This allows for compatibility with new automated balers with no effect on performance or reliability.

Why Machine-Tape Compatibility Matters

The improper tape can lead to:

-

Repeated machine jams.

-

Poor sealing and tensioning.

-

Too much machine component wear.

-

Additional maintenance costs and lost time.

By choosing tape with specifications matching your machine, you are able to get smoother operation, enhanced sealing quality, and increased throughput. Weide Chuangyi Packaging utilizes a system-thinking strategy, providing tapes and solutions customized for every type of machine to achieve maximum efficiency and lower running costs.

System Thinking in Packaging Solutions

What is systems thinking in packaging?

Systems thinking involves looking at the packaging process as a whole system, where everything has to work together in harmony. That includes the strapping tape, the baling machines, the operators, and the weather.

Benefits of compatible machine usage and tapes

If you use matched machinery with comparable consumables like our automatic PP strapping tape, you find smoother operations, fewer malfunctions, better sealing quality—and lastly—more throughput.

How Weide Chuangyi Packaging applies this tactic

Weide Chuangyi Packaging is a packaging material supplier with accompanying R&D, production, and sales. We boast supplying not just products but complete system solutions to fit our individual customers’ machines and working needs. Our products cover everything from fully automatic PP strapping tape that has been specifically designed for compatibility with various automated balers.

Advantages of Using Weide Chuangyi Packaging’s Strapping Tape

Designed with total automation in mind

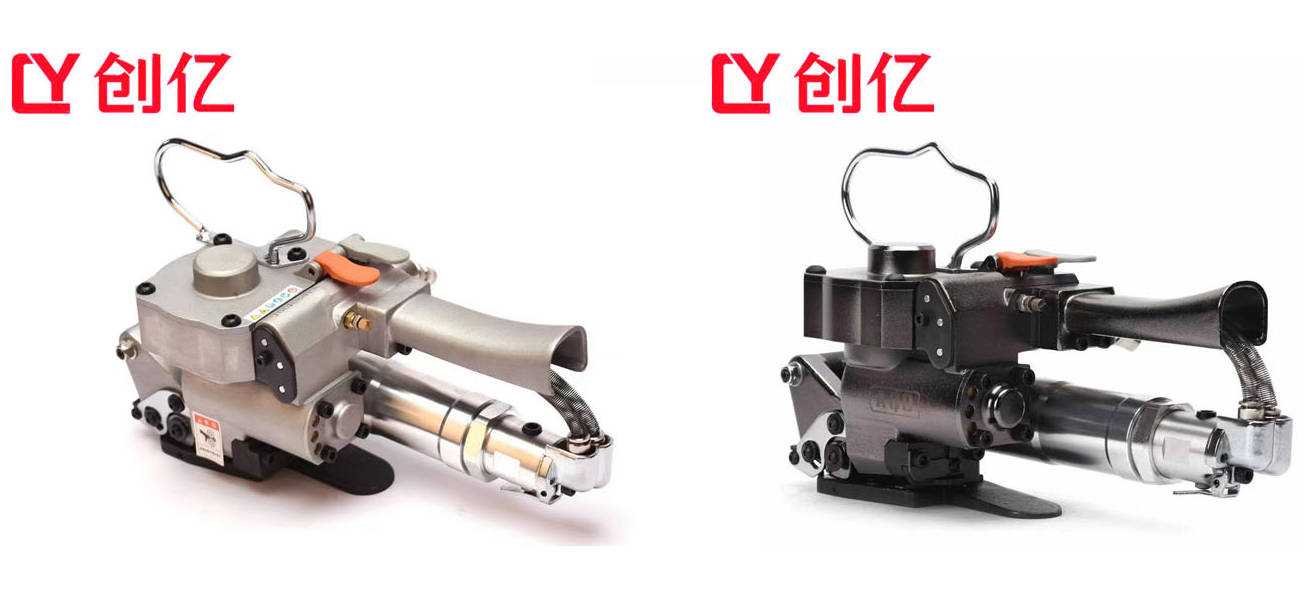

Our totally automatic PP strapping tape is specifically designed for use on high-speed balers like pneumatic balers and electric balers that are offered on our site. These tapes pick up smoothly without creating friction-related problems endemic to lower-quality options.

Consistent quality and performance

Each product undergoes double testing to ensure that the product is of standard quality and exceeds the quality standards. Our customers across industries—logistics to home appliances—rely on us because we offer consistency that can be trusted every time.

Improved uptime and reduced maintenance

By using similarly matched tapes like ours that are specially designed for automated machinery, clients have significantly fewer breakdowns. With my packaging solution, the operational efficiency has been greatly enhanced and man-hours saved—as certified by a hardware business client who shifted their manual system to automation with our help.

How to Choose the Most Appropriate Tape for Your Machine

Key Factors to Consider

-

Width: 6–13 mm based on your machine.

-

Thickness: 0.6–0.9 mm for automatic systems.

-

Strength: Design breaking tension to meet your load requirements.

High-quality PP bands provide strong tensile strength while remaining lightweight, ensuring optimal performance without adding unnecessary weight.

How to Choose the Right Tape for Your Machine Model

Refer to your baler manual or contact our specialists. We offer tailored solutions from color, size, and logo to accommodate your operating needs. Contact us at jaminluo668@gmail.com or +86 13360307579.

Real-World Benefits for Your Business

Faster and more efficient packaging

One of Foshan’s hardware industry customers shifted from manual to total automation with our solution—and now straps four cans at once while improving shipping stability with layer stacking. Due to the strapping of strapping tapes, the packaged iron cans are stable while stacking.

Lower total cost of ownership

Although the upfront cost seems higher than that of manual options, the long-term payoff in terms of reduced labor, fewer repairs, and lower error rates pays for itself. Adequate economic cost per meter, less than steel strapping, lends weight to this claim when compared to options like PET straps.

Greater safety and reliability

Since our tapes are made of polypropylene and not steel, they do not possess cutting edges that can injure employees.PP bands are embraced due to easy applicability, therefore safer with excellent performance under pressure.

FAQ

Q: Can I personalize the color or size of my fully automatic PP strapping tape?

A: Yes! We provide personalized personalization, such as color personalization, size personalization, and even printing of logos if required.

Q: Which industries can benefit most from this product?

A: Our customers include Guangzhou logistics companies, as well as ceramic manufacturers like Oushennuo. Weide Chuangyi Packaging has been offering strapping tapes received by credible ceramic companies like Oushennuo.

Q: How do I know which product is best for my machine?

A: Contact us directly at our official website, email jaminluo668@gmail.com, or call us at +86 13360307579. Our expert consultants will help you with the selection based on your machine model.