5 Signs You’re Using the Wrong PET Strapping with Your Pneumatic Baler

2025-11-27Proper PET strapping is essential to the success of operations, product protection, and tool longevity in packaging processes. The improper strap will lead to breakage, weld compromise, machine abrasion, and lost time. Five indicative signs that you’re not using your PET strapping with a compatible pneumatic baler—and how you can rectify it—are presented below.

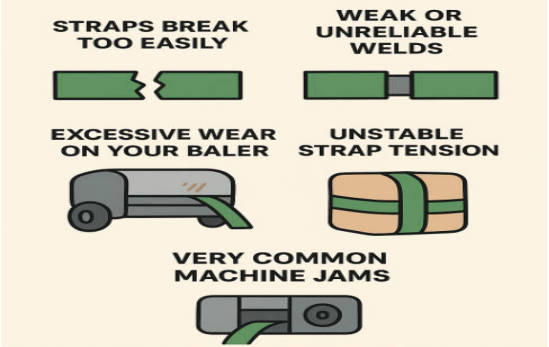

Common Indications of PET Strapping Problems

When you use a pneumatic baler in your packaging operations, the efficiency of your PET strapping is a crucial essential. If you are having issues during strapping, it may indicate that you are using the wrong kind or quality of PET strapping. These five common indications are the ones to watch out for:

PET Strap Breakage Issues

PET straps may snap under tension or during storage due to insufficient tensile strength. Low-quality straps often use recycled polyester, which reduces durability and resistance to breakage. In contrast, high-quality PET straps made from virgin (new, non-recycled) polyester provide consistent tensile strength, protecting your packages throughout transport and storage.Always use PET straps from reputable manufacturers that adhere to strict manufacturing standards and perform rigorous quality testing. This reduces the risk of breakage and ensures safe handling.

Tip: Pneumatic strapping machines are suitable only for PP and PET straps. Materials such as steel or other polyester fibers cannot be used due to different welding methods.

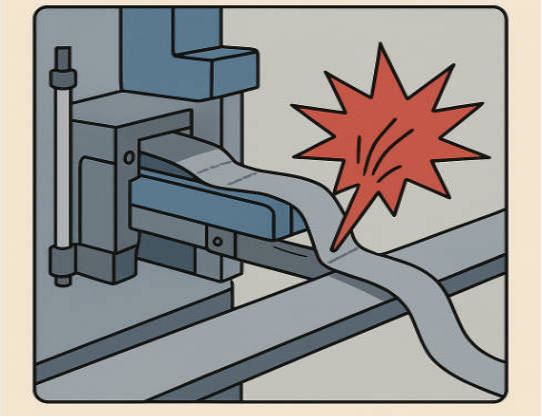

Weak or Unreliable Welds

PET straps are sealed by friction welding in pneumatic balers. Weak and inconsistent welds are often a result of low-grade or incompatible strapping. Impurities, irregular thickness, and poor-quality surface material in strapping inhibit bonding and cause loose packages.

Solution: Spend money on PET straps that are designed solely for pneumatic balers. They should have smooth surfaces, equal thickness, and top-of-the-line raw materials to guarantee a successful welding process every time.

Excessive Wear on Your Baler

If your pneumatic baler needs constant maintenance or is destroyed earlier than anticipated, the issue might not be your machine but your strap. PET strapping of poor quality with sharp edges or irregular surfaces may ruin internal parts, leading to more downtime and maintenance expenses.

Advice: Use straps with smooth edges, double-sided embossing, and equal dimensions. These make the strap less frictional, increase tool life, and maintain your operations uninterrupted.

Unstable Strap Tension

Even tension is necessary for giving secure and safe packaging. Loose straps shortly after packaging or tension variation between packages can be caused by uneven strap thickness or poor elasticity, and that is most likely the case. PET strapping tape with accurate specifications maintains tension over extended distances and protects your products during storage and shipping.

Tip: Check your strap width (13–25mm) and thickness (0.4–1.5mm) supported by the baler before purchasing. The right size ensures uniform tension and reduces breakage or jamming risks.

Very Common Machine Jams

A good pneumatic baler should also weld and feed straps easily. Extremely frequent jamming generally indicates uneven quality of the straps or incompatibility with your equipment. Skewed surfaces, uneven thickness, or incorrect embossing can cause the strap to slip or jam while in use.

Solution: Buy PET strapping compatible with your machine specifications and consistent in quality. Properly designed straps minimize jams, save labor, and maintain production at an even level.

Causes of PET Strap Failures

Most issues with PET strapping arise from one of four primary causes:

-

Low-Quality Materials: Straps made from recycled PET are cost-effective but often have poor and inconsistent tensile strength.

-

Incompatibility with Pneumatic Balers: Not all PET straps are suitable for use with pneumatic strapping machines. Only PP and PET straps can be welded with pneumatic heat sealing equipment. Ensure the strap’s width, thickness, and embossed surface meet equipment requirements.

-

Incorrect Strap Sizes: Insufficient width or thickness may lead to improper sealing or strap failure. Industrial applications are best served by standard strap widths such as 1508 mm, 1608 mm, 1609 mm, and 1910 mm.

-

Environmental Conditions: Low-quality PET straps may degrade due to heat, humidity, or prolonged storage. High-quality PET straps maintain consistent performance under these conditions.

Note: Pneumatic strapping machines are suitable only for PP and PET straps. Steel straps or other polyester fiber straps cannot be used due to incompatible welding methods.

How to Choose the Proper PET Strapping

Choosing proper PET straps will provide smooth handling and package integrity.

Strap Specifications for Your Model Baler

Ensure that the thickness as well as the width of the strap are in harmony with your requirements for a pneumatic baler. As noted above, our Pneumatic baler utilizes a strap thickness range of 0.4-1.5mm and a strap width capacity of 13-25mm. Satisfying these specs avoids jamming and guarantees sealing.

Get Consistent Strength and Quality

Seek out features like double-sided embossing for anti-slip functionality and smooth edges that won’t contaminate products or machinery. Double-sided embossing, transparent texture, and great anti-slip performance are some of the common features of Weide Chuangyi Packaging brand PET packaging belts.

Choose Reputable Brands like Weide Chuangyi Packaging

We at Weide Chuangyi Packaging have been producing high-performance packaging materials since 2004, with over two decades of R&D and production expertise. We specialize in producing PP strap, PET strap, Stretch Film, Paper corner protector, etc., packaging products, all rigorously tested for quality assurance.

Advantages of High Quality PET Strapping from Weide Chuangyi Packaging

By using our PET strapping belt, you’re investing in dependability across every part of your packaging process.

Improved Tool Life and Functionality

Smooth faces and uniform dimensions of our straps reduce wear on air tools by far, significantly improving tool life.

Improved, More Consistent Welds

Through our virgin-grade polyester composition and strict quality control procedures, the tensile strength and texture of our strapping tape are greater than those of recycled-material products, producing strong welds consistently.

Lower Downtime, Lower Maintenance Fees

Less jamming, less downtime. Precise sizing like 1608 or 1910 ensures our straps will fit with minimal or no manual adjustment using most pneumatic balers—both saving time and labor dollars.

Enhanced Safety and Load Stability

Our PET straps have steel-like tensile strength but no sharp edges. Even when stretched to the limit, it won’t hurt people when cut off. They also possess long-distance tensile maintenance so that commodities possess very good impact resistance when being transported over a long distance.

FAQ

Q: How do I know which model of PET strap will be suitable for my pneumatic baler?

A: Check your machine’s supported width (usually 13–25mm) and thickness (usually 0.4–1.5mm). Our sizes, like 1608, 1609, or 1910, support the most industry-standard ranges.

Q: Do I have the facility to customize the color or logo on my straps?

A: Yes! We provide customized personalization like color customization, size customization, and logo customization so that you can match packaging with your brand identity.

Q: Are these products eco-friendly?

A: Yes.PET strapping tape is recyclable and environmentally friendly, and hence a wonderful alternative to steel bands, yet sustainable in purpose.

Q: How do I get Weide Chuangyi Packaging’s products?

A: Visit our official site to see our whole product line, like PET packing belts, pneumatic balers, strap buckles, stretch film rolls & more!