Which Strapping Belt is Best for High-Stress Packaging: PP or PET?

2025-08-07

Addressing Packaging Challenges in Modern Logistics

Common Risks of Storage and Transportation

In today’s globalized supply chain, packaging must withstand long-distance shipping, handling multiple times, and exposure to the elements. Among the perils are moisture exposure, dust contamination, transit movement, and stacking pressure that can void product integrity. For light or fragile products like ceramics or machinery, packaging breakdown can result in costly damage or downtime.

The Application of Strapping Belts in Cargo Securing

Strapping belts are the first choice for stabilizing and securing merchandise in transportation and storage. For tying up cartons or pallet palletizing, an adequate strapping material ensures security, reduces loss, and enhances handling productivity. The choice between PP (polypropylene) and PET (polyester) strapping belts depends on the specific needs of the cargo as well as transportation conditions.

Company Overview: 21 Years of Experience in Customized PP/PET Strapping Solution

Foshan Weide Chuangyi Packaging Materials Co., Ltd., founded in 2004, is a professional manufacturer specializing in PP strap, PET strap, fully automatic PP strap, semi-automatic PP strap, stretch film, and paper corner protectors. With a 10,000 square meter independent factory and over two decades of experience, we provide customized packaging solutions tailored to logistics, electronics, home appliances, ceramics, hardware industries, and more.

Understanding the Core Types of Strapping Belts

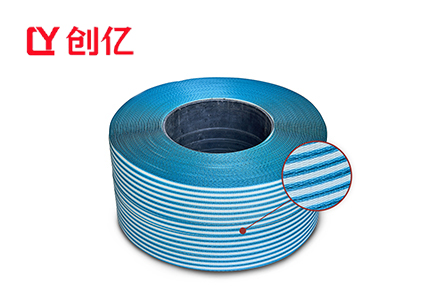

Features and Applications of PP Strapping Belts

Material: Polypropylene (PP)

PP strapping bands are made primarily from polypropylene resin—a lightweight plastic known for its good plasticity, high tensile strength, bending resistance, low density, and ease of use.

Key Characteristics: High Flexibility, Bright Colors, Anti-Slip Texture, Cost-Effective

Packing straps have good plasticity, strong breaking tension, bending resistance, low density, and good tensile impact properties. Clear surface pattern with anti-slip design ensures secure bundling. These features make PP belts both economical and effective for light-duty applications.

Common Sizes: 1206, 1208, 1507, 1508, 1510 (customized available)

We offer standard specifications like 1206 to 1510 with customized options based on customer requirements.

Compatible Tools: Manual, Semi-Automatic, and Automatic Strapping Machines

Manual strapping machines are compatible with PP straps ranging from 12 to 16mm in width. For higher efficiency needs, our straps support semi-automatic and fully automatic balers as well.

Ideal Use Cases: Light Industrial Goods, Food Packaging, Textiles, Retail Packaging

PP straps are widely used across industries requiring lightweight yet secure packaging, such as department stores, food processing units, printing houses, pharmaceuticals, textiles, and logistics.

Features and Applications of PET Strapping Belts

Material: Polyester (PET)

PET strapping bands are high-strength alternatives to steel straps made from polyester resin.

Key Characteristics: Steel-Like Strength, 5% Tension Retention Rate, Weather Resistance, Recyclable

They maintain 5% tension without loosening and offer elongation under strong impacts to ensure cargo safety. Excellent weather resistance allows use between -50℃–100℃ while maintaining stability.

Cost Efficiency: One Ton = Length Equivalent to Six Tons of Steel Belt

One ton of PET strap equals the length of six tons of steel straps—reducing cost by up to 60% while improving handling safety.

Compatible Tools: Pneumatic and Electric Strapping Machines

Our PET belts are designed for pneumatic balers operating at 0.5–0.8MPa or electric balers offering tension speeds up to 200mm/s for precision control.

Ideal Use Cases: Heavy Loads like Ceramics, Metals, Machinery; Long-Distance Transport

PET straps are optimal for securing heavy-duty goods such as ceramics, metal components, and industrial equipment, especially during prolonged transit.

Matching the Right Belt to Industry Demands

Logistics Sector Requirements

A logistics company in Guangzhou adopted our eco-certified PP belts that comply with EU standards for global shipments—ensuring safe delivery while meeting export regulations.

Home Appliance Packaging Needs

Lightweight but bulky items like HVAC units or battery packs benefit from our customized PET or PP straps that offer secure bundling without adding excessive weight.

Ceramic Industry Demands

Our PET belts have been trusted by ceramic leaders like Oushennuo since 2017 for their dustproofing capabilities during storage and moisture resistance during shipping.

Hardware and Metal Products Packaging

For stacked metal containers requiring automation compatibility—our machine-grade PP straps paired with galvanized steel seals deliver efficiency at scale.

The Importance of Customized Solutions in Packaging

Customization Options for Branding and Functionality

Our products come with full customized options:

- Customized colors including white/yellow/red/blue/transparent

- Customized logo printing for enhanced brand visibility

- Customized widths & thicknesses tailored to specific machine models

- Customized lengths based on application volume needs

Enhancing Efficiency with the Right Tools and Accessories

Tool Combinations Based on Usage Volume and Belt Type

- Manual Tool + PP Belt → Ideal for low-volume mobile operations due to portability without power dependency.

- Pneumatic Tools→ High-speed tensioning for PET/PP belts

- Electric Tools → Accurate tension control at speeds up to 200mm/s

Essential Accessories for Secure Strapping Results

- Galvanized steel seals: Enhance locking strength with PET belts

- CNC-cut paper edge protectors: Provide recyclable corner protection against compression damage during stacking

Five-Step Checklist for Choosing the Right Strapping Belt Solution

- Assess load weight & fragility.

- Determine transport distance & environmental exposure.

- Choose appropriate material – PP for light loads; PET for heavy-duty.

- Match belt size & thickness with equipment

- Opt for customized branding & accessories if needed.

FAQ

Q: What’s the difference between a PP strap and a PET strap?

A: PP is lighter with high flexibility suited for light goods; PET offers steel-like strength ideal for heavy-duty loads over long distances.

Q: Can I use manual tools with both types?

A: Yes. Manual tools work effectively with both PP & PET straps, ranging from widths of 12–19mm depending on application needs.

Q: Are your strapping solutions eco-friendly?

A: Absolutely. Our products meet EU environmental standards, ensuring no harmful substances are used—making them suitable even for export packaging.

Q: How do I choose between pneumatic and electric tools?

A: Pneumatic tools are ideal for fast-paced operations using compressed air; electric tools provide precise tension control—best when accuracy is critical.

Q: Do you offer customized logo printing on straps?

A: Yes. We provide fully customized solutions, including color matching and logo printing tailored to your branding requirements.