Why Strapping Material Choice Matters More Than You Think?

2025-09-12

Understanding Strapping Materials

What Is Strapping Material

Strapping material refers to the bands or tapes used to bundle, secure, and stabilize products during packaging, storage, or transportation. These materials are essential in preventing product damage and ensuring safe handling across various industries. The selection of the right strapping material depends on factors such as load weight, environmental conditions, and the type of goods being packaged.

Common Applications in Packaging

Strapping materials are widely used in industries such as logistics, electronics, home appliances, furniture, ceramics, and hardware. There are many packaging materials that we are familiar with, such as Weide Chuangyi Packaging‘s strapping tape, wrapping film, sealing glue, etc. For instance, a logistics company in Guangzhou adopted Weide Chuangyi Packaging PP strapping for its high-volume shipments due to its compliance with European environmental standards and excellent performance. Because of the large number of sales to all parts of the world, the requirements for strapping are also very high.

Why Material Selection Is Crucial

Choosing the correct strapping material directly impacts product safety, cost-efficiency, and operational productivity. Selecting high-quality, cost-effective strapping bands in a diverse market is crucial. The wrong choice can lead to package failure or increased costs due to over-specification.

Main Types of Strapping Materials

Type 1: Plastic Strapping

Features of Plastic Straps

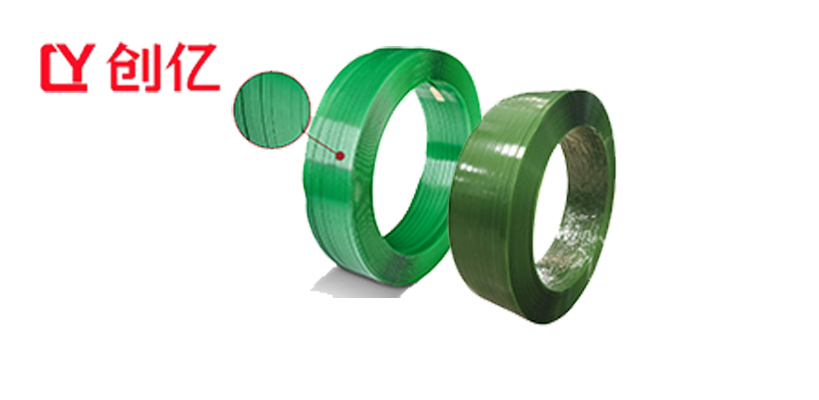

Plastic strapping includes PP (Polypropylene) straps and PET (Polyester) straps, both offered by Weide Chuangyi Packaging. PP bands are widely used due to their good plasticity, high tensile strength, bending resistance, light weight, and ease of use. On the other hand, PET straps offer steel-like tensile strength and impact-resistant extensibility. Weide Chuangyi provides various models like PP strap 1206/1208/1507/1508/1510 and PET strap 1508/1608/1609/1910, with color customization options available.

When to Use Plastic Strapping

Plastic straps are ideal for bundling lightweight to medium-weight goods such as cardboard boxes, electronics, textiles, and food items. Scope of application: outer packaging for household appliances, the light industry, food, and department stores. PET straps can also be used for heavier items like ceramic tiles or wood panels, where steel replacement is needed.

Benefits of Using Plastic from Weide Chuangyi Packaging

High-quality PP raw materials produce packing tapes with bright colors, stronger, and more durable. Their PET straps are made from virgin polyester for better texture and tensile strength compared to recycled versions. They feature double-sided embossing with good anti-slip performance, resistance to weather changes between -50℃–100℃, and do not rust or damage hands during operation.

Type 2: Steel Strapping

Characteristics of Steel Straps

Steel strapping is known for its superior strength and rigidity. It’s best suited for heavy-duty applications where maximum holding power is required. Unlike plastic alternatives, steel does not stretch under tension but may corrode if exposed to moisture.

Ideal Uses for Steel Strapping

Steel strapping is commonly used in industries like construction materials (bricks or metal), machinery parts shipping, and bundling sharp-edged products such as cut iron sheets. For example, a canning factory in Foshan used plastic steel strapping tapes from Weide Chuangyi Packaging to strap cut iron sheets for more convenient transportation.

Advantages of Weide Chuangyi Packaging Steel Straps

Weide Chuangyi offers compatible strapping buckles made from galvanized steel in sizes like 16mm×0.5mm, 19mm×0.5mm, ensuring a secure seal during transport. Simply place the split clamp on the overlapping strap ends before or after tensioning and crimp it into place with a hand tool. This makes their steel solutions both efficient and reliable, even under heavy loads.

Type 3: Woven and Composite Strapping

What Are Woven and Composite Straps

Woven straps use synthetic fibers woven together, while composite straps have a polyester core coated with polypropylene. These types combine flexibility with high tensile strength without damaging delicate surfaces.

Best Situations to Use Them

They’re ideal when cargo requires shock absorption during transit—especially useful for exports via sea freight where movement is constant. Their flexibility makes them suitable for irregularly shaped goods or fragile items that cannot withstand rigid tensioning.

Why Choose Weide Chuangyi Packaging Options

While woven/composite options aren’t explicitly listed among current offerings at Weide Chuangyi Packaging, they provide Poly Strapping Tools (tensioners/sealers) compatible with all types of bands, including flexible fiber ones. This shows their commitment to comprehensive packaging solutions even beyond traditional materials.

Comparing the Three Types

Strength and Durability Comparison

Steel has unmatched tensile strength but lacks flexibility; PET offers comparable strength with added safety benefits; PP is best suited for lighter loads. The length of 1 ton of plastic steel strapping tape is equivalent to the length of 6 tons of steel strapping, making PET an efficient alternative.

Cost-Effectiveness Analysis

Manual PP bands (like PP strap 1507) are low-cost options ideal for small businesses. Manual bands have a tensile strength of 50kgtransparent bands about 2500m. PET offers long-term savings due to recyclability, and the cost per meter is lower than that of steel strapping. Steel remains expensive due to material cost, but it is necessary in specific scenarios.

Suitability for Different Industries

①Logistics: PP/PET

②Ceramics & Wood: PET

③Machinery & Hardware: Steel/PET

④Electronics & Appliances: PP

Weide Chuangyi Packaging has been supplying strapping tapes to well-known ceramic companies to reduce costs.

Choosing the Right Strap for Your Needs

Factors to Consider Before Buying

Key considerations include:

①Load weight & shape

②Environmental exposure

③Required tension retention

④Compatibility with tools/machines

Key Considerations for Choosing Strapping Band Specifications: include width (e.g., 13–16mm), thickness (e.g., 1.2mm), tensile strength (50–150kg), etc.

Industry-Based Recommendations

①E-commerce/logistics: Use fully automatic PP strapping tape.

②Ceramics/furniture: Go for the PET strap 1609.

③Metalworks/hardware: Choose a steel buckle + PET strap combo.

How Weide Chuangyi Packaging Helps You Decide

Foshan Weide Chuangyi Packaging Materials Co., Ltd is a packaging material supplier integrating R&D, production, and sales. With over two decades of experience, We have been creating customized high-quality strapping tapes for customers, offering personalized solutions based on client needs—from product specs down to color/logo customization. Contact us at +86 13360307579 or jaminluo668@gmail.com.

FAQ

Q: What’s the difference between PP and PET straps?

A: PP bands are lightweight with good plasticity; PET straps have higher tensile strength, similar to steel but safer handling.

Q: Can I use your products with automatic machines?

A: Yes! Products include fully automatic PP strapping tape, Pneumatic baler, PET strap, Pneumatic baler

Q: Do you offer eco-friendly options?

A: Absolutely. Our company took “providing customers with products suitable for their use” to meet EU environmental protection standards

Q: Are your products customizable?

A: Yes.Custom PP/PET strapping. Color specification customization available upon request!